A theory behind epoxy coating peel off

You’re about to invest in a new epoxy floor. Upon checking the substrate, your applicator tells you that your concrete is ‘rubbish,’ and now, as with so many tradies, you’re wondering if this is just another cash grab or if there is merit to the story.

Your first response is to suspect the epoxy applicator. You don’t know what you don’t know, but you don’t want to go blind becoming an epoxy expert for something that seems so innocent and straightforward. Right? You could be pointing the finger at the wrong contractor.

Here’s something to ponder regarding epoxy coating peel off and failures.

Bad concrete or bad application?

Peeling epoxy could be the fault of an inexperienced, unskilled epoxy applicator – or it could be the fault of poor concreting practices. Here’s how to tell the difference:

- If the coating comes off and has clear epoxy on the back, the epoxy applicator is likely to blame. This indicates an adhesion issue and could be attributed to poor preparation, along with a multitude of missteps and mistakes.

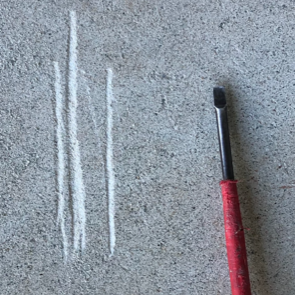

- If the coating comes off and has concrete stuck to it (see photo above), the concrete is likely not to an acceptable standard. This indicates that the epoxy coating is stronger than the concrete.

Why is my concrete so weak?

If the above test proved that it’s the concrete – and not the epoxy coating – at fault, you might be left wondering, “Why is my concrete so weak?”

Weak concrete that isn’t to code can be caused by several factors, one of the most common being overwatering the concrete before it’s laid. The process of watering down concrete causes the “fines” – the finest particles – to rise to the surface, creating a weak crust. This type of concrete requires about 5mm of grinding to be made strong, which might not sound like much, but it’s a lot of work.

The concrete truck leaves the batch plant, and all quality checks are in place. It’s, say, 20MPa and full of all the ingredients that suggest that this is a quality batch.

Sometimes, the incorrect use or application of accelerants and retardants could also contribute to poor quality concrete. There are many of these products and keeping track of what was used, and how much, is extremely difficult.

In our experience, overwatering the concrete is common when it turns up to the site. It becomes easily workable, and who would blame someone for making their work easier?

However, this has ramifications and not necessarily with the concrete, but with the coating and, importantly, the preparation required to adequately coat. That being said, over time, the concrete can also degrade.

We see this in both new and old homes but is more common in new slabs. An area of quality checking failure sometimes lies with the builder’s failure to manage and supervise the contractors they use, yet defend them when issues arise. We believe that helping builders to understand the implications of poor concrete is part of our obligation to the industry and our valued customers.

Work with epoxy contractors you can trust

The dedicated team behind Tough Floors are epoxy experts – it’s all we do. When you work with us, you know you’re getting the highest industry standard of workmanship. Get in touch today for a fast and accurate quote.