Trusted By

Floor Colours and Finishes

These days epoxy flooring provides you with so many choices when it comes to finish colours, effects and designs. The possibilities are infinite.

We offer you the options to consider, which are plenty. We also make recommendations & these are based on areas of safety, historical proven choices, any applicable standards we will need to work to & ultimately, what you're seeking in terms of aesthetic appeal & functionality.

Below is a summary of important information & areas for consideration when choosing your epoxy floor finish.

Floor Colours & Finishes

In Australia, we currently have two main types of flake:

- An imported Polyvinyl Acetate (PVA)

- An Australian manufactured acrylic latex

There are also new styles coming from Asia. We undertake extensive investigation and testing of new products using stringent quality control, performance and supply criteria, before we decide whether to add new products to our range of finish options.

Flake is UV proof so in terms of adding to a floor that has decent exposure to UV, this is a good thing and means that epoxy floor can maintain its colour longer than some other flooring types which fade in sunlight. The top coat used to seal the flake into the floor tends to absorb less into the PVA flake than the acrylic latex, so this is important in terms of ‘costs per floor’ being reduced.

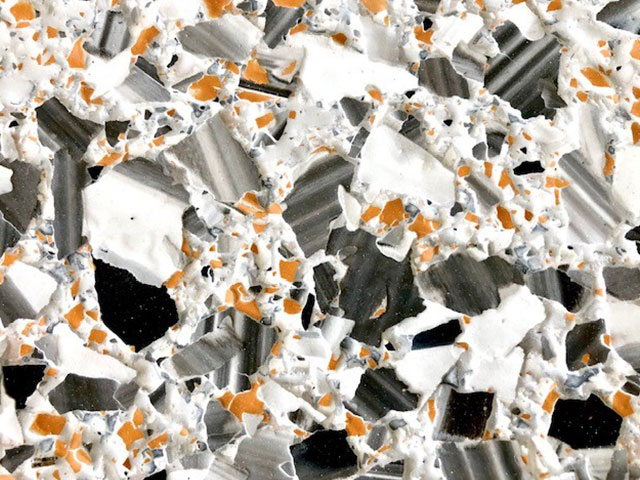

There are so many possibilities of flake finishes available. Scroll down to see our unique ranges including Garage Blend, Refined Blend & Outback Blend. Within these ranges, there are plenty of standard colours along with options to create something unique to your floor.

From the customisable perspective, there are flake options including two toned, metallic & of course, glow-in-the-dark. Yes, glow-in-the-dark, which currently comes in two colours including blue & a yellowy-green.

This flake is charged by light & once darkness hits, the flake glows quite brightly before settling & remaining luminescent for around 8 hours.

During the day, the flake is white.

Aside from the colours & styles, there are size differences from micro to an almost crushed dust to an XL size whereby some flake pieces are the size of a 50 cent coin.

In Australia, the medium sized 6mm style is very common & typical in garage & patio environments.

Flake mostly comes pre-mixed in various pack sizes. An experienced flooring applicator will know that there are differences in how to apply & spread the various sized flake in order to get the best finish.

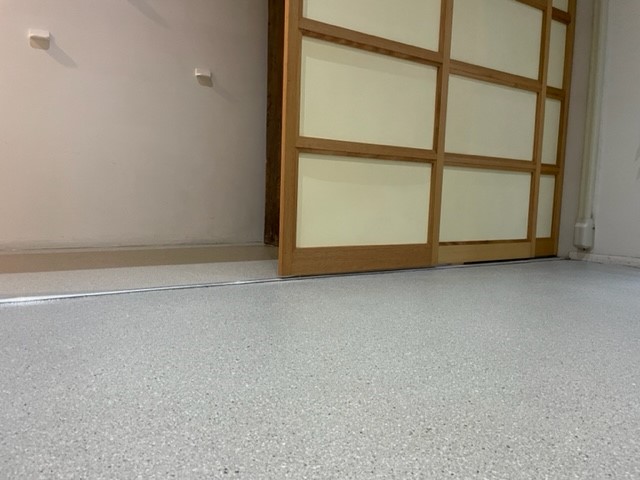

Full Coverage - when a floor is fully saturated with flake, this isn't just the most popular option, it's also the most cost effective, protective & resistant to the elements.

Partial Coverage - when a partial flake option is preferred, there can be numerous reasons for this including:

- Wanting to see more of the base coat colour coming through

- Wanting a less busy design for aesthetic reasons

- For functionality such as in commercial environments where it's imperative that smaller items, when dropped, need to be located as opposed to camouflaged against the design & colours.

There are so many options & designs. Some other finishes possible include:

- Straight colour finish in high gloss

- Straight colour finish with a polish applied to dull the final result, similar to a matt finish

- Partial flake with XL flake

- Straight colour flake

- Same colour base coat with same colour flake

- Standard colour finishes with a % of an additional single colour for effect

- Added glitter

- Decals

...and much much more

Flake Finish

Other finishes

When you have the right tools, products and knowledge at your disposal, the possibilities become endless. We can work with you to create a totally unique style, colour and effect, as you can see in some of these project examples below.