Floor Colours and Finishes

These days epoxy flooring provides you with so many choices when it comes to finish colours, effects and designs. The possibilities are infinite.

What is most important is that the final finish is appropriate for the location usage, meets any Standards compliance requirements, is installed professionally and provides an aesthetic that you love.

There are three key components to choosing an epoxy floor finish

- the base epoxy coat colour and properties

- the flake size, colour and mix

- additional finish features to meet location and usage requirements, and Standards (if applicable).

Here’s a summary of the important facts, and things we take into consideration when choosing the right epoxy floor finish for you.

In Australia, we currently have two main types of flake:

In Australia, we currently have two main types of flake:

- An imported Polyvinyl Acetate (PVA)

- An Australian manufactured acrylic latex

There are also new styles coming from Asia. We undertake extensive investigation and testing of new products using stringent quality control, performance and supply criteria, before we decide whether to add new products to our range of finish options.

Flake is UV proof so in terms of adding to a floor that has decent exposure to UV, this is a good thing and means that epoxy floor can maintain its colour longer than some other flooring types which fade in sunlight. The top coat used to seal the flake into the floor tends to absorb less into the PVA flake than the acrylic latex, so this is important in terms of ‘costs per floor’ being reduced.

The colour range possibilities of flake finishes is enormous.

The colour range possibilities of flake finishes is enormous.

If you scroll down you’ll see the two blended ranges we have developed called Garage Blend and Refined Blend, which are highly popular with our clients.

In essence there are marble style two toned flakes, metallic flakes and glow-in-the-dark. Yes, glow-in-the-dark!This comes in two colours currently which are a yellowy-green and blue. The flake is ‘charged’ by light and once darkness hits, the flake glows quite bright initially before settling down and remaining luminescent for around 8 hours. This photo, taken at night in a client’s warehouse, shows the beautiful blue glow-on-the-dark flake. During the day it is white.

Aside from the colours and styles, there are also size differences from micro to almost crushed dust and, at the other end of the scale there’s XL size - which has chunks as large as 50 cent pieces. In Australia, the most common flake size used is 6mm.

The flake comes pre-mixed in 5, 10 and 20kg lots and straight onto the floor after coating. However with the XL, this cannot be thrown out in the same way you disperse the 6mm flake. It needs to be dispersed differently, as experienced installers know.

Flake is a product that can be used in different ways to achieve remarkably different final effects.

Flake is a product that can be used in different ways to achieve remarkably different final effects.

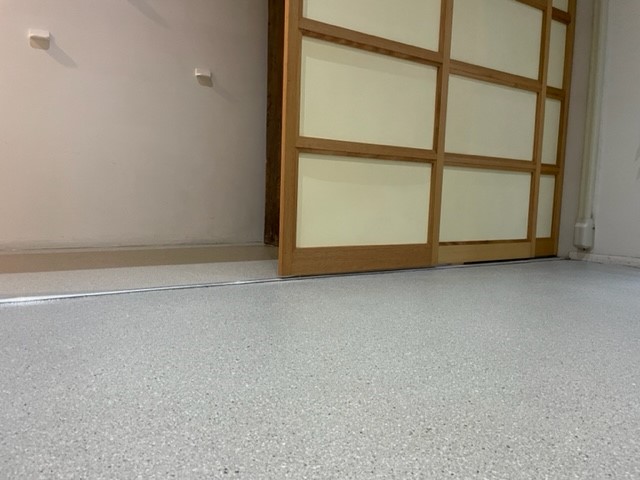

Full coverage: 100% flake coverage is not only cost effective, but also provides additional protection by adding a layer between the foot, vehicle and equipment traffic and the resinous coating. The flake size and colours determine the final look, as you can see with the Garage and Refined blends below.

Partial coverage: Some clients prefer a partial flaking finish for reasons such as:

- Wanting to see more of the coloured base coat

- Wanting a less busy design for aesthetic reasons

- The flooring is in an area where small items may be dropped, and need to be easily found rather than being camouflaged against the design.

If you’re looking for something different and unique, a solid epoxy resin floor without flake provides a high gloss and impressive finish.

Alternatively incorporating metallic pigments into the resin can create elegant and exotic colour combinations. This is an eye-catching option for an environment where a statement floor is an asset.

Alternatively incorporating metallic pigments into the resin can create elegant and exotic colour combinations. This is an eye-catching option for an environment where a statement floor is an asset.

It’s also possible to customise epoxy floors to create designs which resemble marble, stone, granite and even water.

Note: these high end designs do take extensive training and experience to achieve.

Flake finish

Other finishes

When you have the right tools, products and knowledge at your disposal, the possibilities become endless. We can work with you to create a totally unique style, colour and effect, as you can see in some of these project examples below.